Environment

Living the Implats Way

Our purpose is to create a better future. We accomplish this through the metals we produce, the way we do business and through our superior performance.

Read moreSouth Africa 0800 005 314

Zimbabwe 0772 161 630

Impala Canada 1-866-921-6714 (toll free) or email the operation at email address:

Impalacanada@integritycounts.ca to lodge complaints or grievances.

For more information on how we handle reports and protect whistleblowers, please review our Fraud, Corruption and Whistleblowing policy

Our environmental policy reflects the Group’s commitment to responsibly manage natural resources and proactively mitigate the environmental impacts associated with our activities.

Read more

Climate change is a critical challenge for the energy-intensive mining and minerals processing sector, demanding lower GHG emissions, greater climate resilience, and transparent stakeholder engagement.

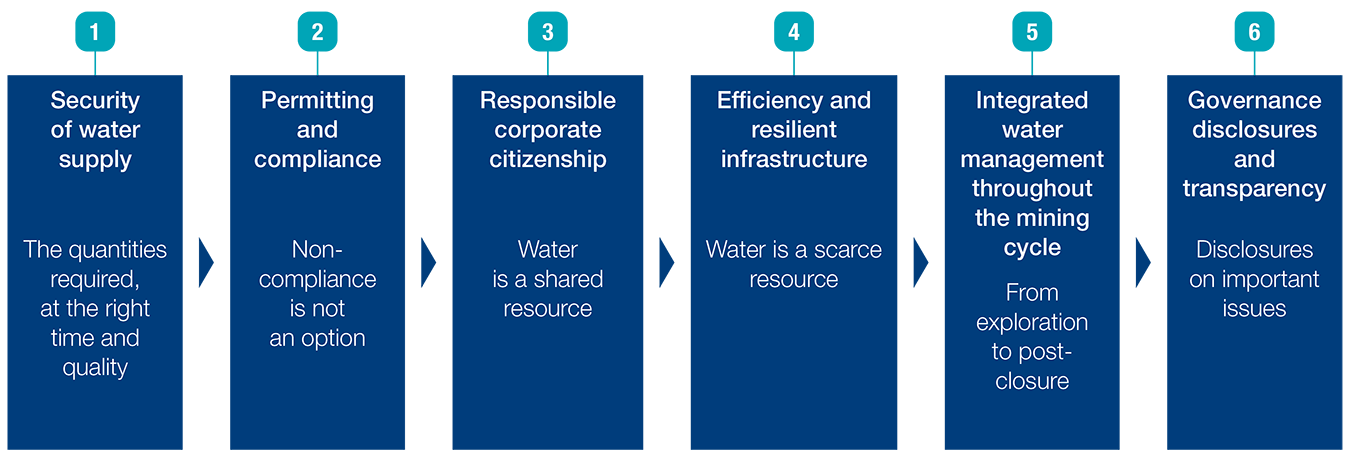

Read moreOur southern African operations are situated in regions facing significant water stress. Implats is committed to responsible water stewardship by prioritising water recycling and re-use at our operations, while also working to reduce our reliance on freshwater sources.

Water recycled or re-used: 59%

against a Group target of 56% water recycled or re-used in 2025 (2024: 55%)

Water recycled/re-used, all operations: 44 718ML

(2024: 40 182)**

** Maiden inclusion of Impala Bafokeng.

Our decarbonisation and energy security policy statement affirms our commitment to transitioning towards renewable and low-carbon energy sources, while ensuring clear and consistent communication regarding the potential impacts of climate change on our business.

Completed commissioning of

35MW

solar plant at Zimplats with board approval for the construction of

45MW

solar plant at Zimplats

281 539tCO2e emissions avoided

through energy efficiency and market-based renewable electricity initiatives.

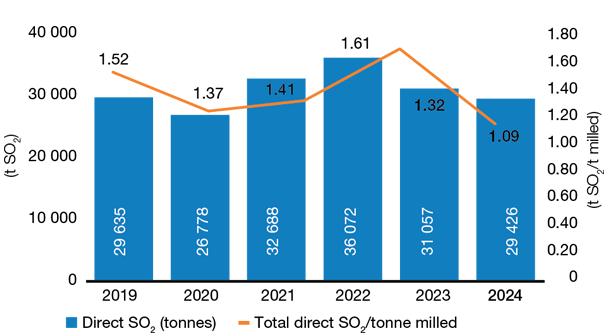

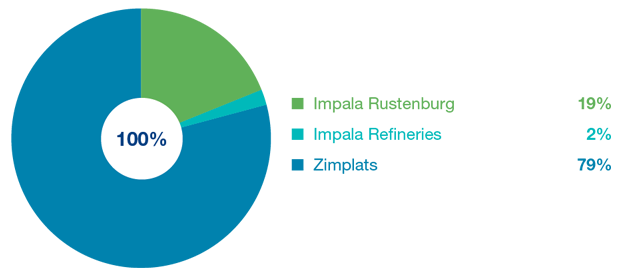

We minimise our air quality impacts by optimising our processes and installing best-in- class abatement technologies.

No dust fallout incidents recorded

at Impala Rustenburg, Impala Bafokeng and Zimplats

Impala Refineries’ air emissions licence (AEL)

successfully granted and valid until February 2030.

SO2

as at 30 June 2025

Direct SO2 emissions

as at 30 June 2025

Implats’ tailings storage facilities are robustly engineered and effectively managed. The Group is firmly committed to achieving full alignment with the Global Industry Standard on Tailings Management.

Zero major or significant environmental incidents

involving TSFs: (2024: zero)

Re-mining of tailings at dormant TSFs

at Impala Rustenburg continues to support local employment.

Integrating mine-closure considerations into the design, planning and operation of our mines is essential to minimising long-term environmental and socioeconomic risks, while ensuring a positive legacy.

Rehabilitated 46ha of eligible land at Group-managed operations

(2024: 39ha)

Community upliftment project at Marula provided employment for community members to seed tailings side slopes